The FinnRecycling reclamation plant has offered valuable possibilities in development and scientific research as the production process evolves. The experiences there have helped in academic growth.

Even difficult theoretic principles in sand reclamation have not been a hurdle to start doing testing and undesirable results have never let the positive mindset for development go down. Experimenting, learning and developing have paved the way for a significant new sector to industrial symbiosis in Finland and advances in sustainability and circular economy are vast.

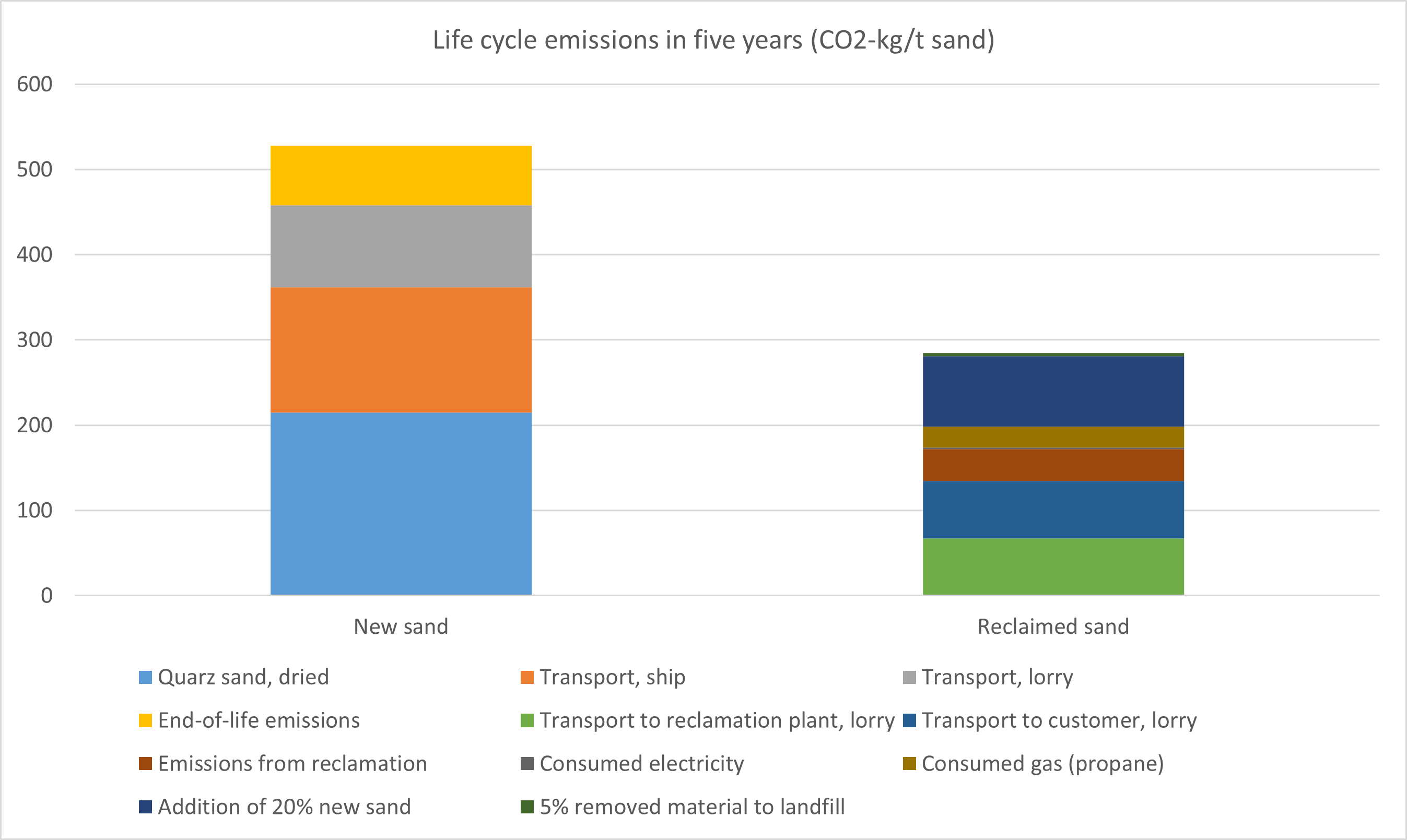

Figure 1

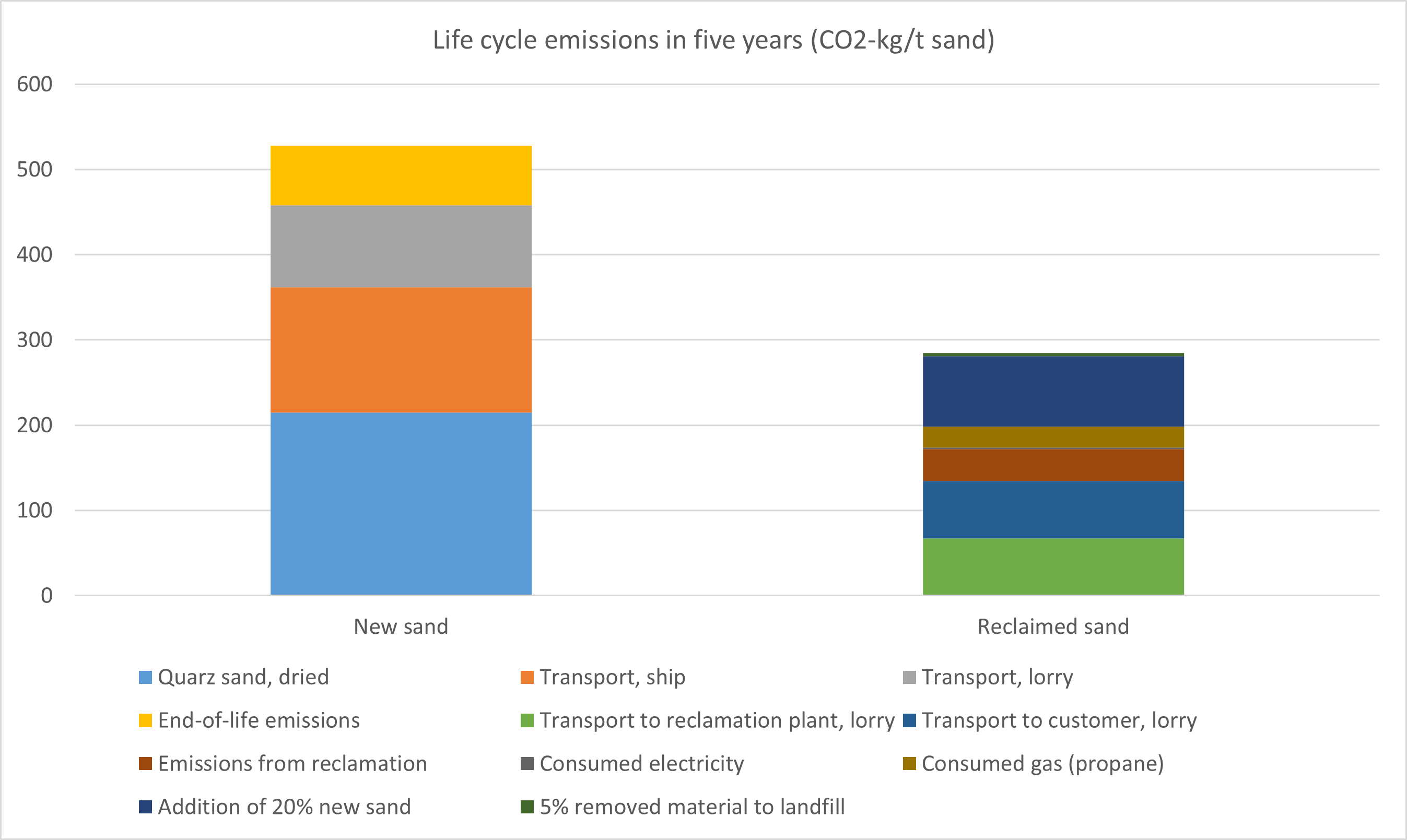

Figure 2

The visual difference in sand quality from the early days of the project have led to the calculations on life cycle savings in some newer projects (figures 1 & 2). If the LCA results are scaled to whole Finland’s foundry production in five years; so five years of bringing in new sand versus reclaiming one years sands over the course of the next years, we could save over 16 million kilos of CO2 emissions. That is the same emission you would get from driving a car to the moon and back 175 times.

– Tommi Sappinen, Doctoral Candidate, Aalto University